SkyWay Technologies

SkyWay consists of a complete range of different technologies. Below we will give you a short overview of everything SkyWay has to offer.

High Speed Transport

The complex comprises:

1 Rolling stock.

2 Track infrastructure.

3 Safety and complex control system.

The rolling stock – unibus – an automated self-propelled module on steel wheels of mounted type is designed for operation solely on the infrastructure of the SkyWay complex and provides for the transportation of people. The motion drive of the unibus is electromechanical, with the supply of power from contact catenary and/or battery packs.

Track infrastructure is designed to service the users of the SkyWay complex. It is a pre-stressed continuous bearing rail-string structure mounted on supports above the ground at the projected height according to customer requirements, and stations (logistics terminals).

The safety and complex control system is designed for automatic control of rolling stock, automated control of the power supply system, collection, storage, analysis of data on component parts of the complex and development of control and corrective actions to ensure safe operation mode of component parts and the complex as a whole.

Sphere of application:

High-speed transportation of passengers:

1 between cities;

2 between regions;

3 between countries;

4 between continents.

Key features:

1 Speed — up to 500 km per hour.

2 Capacity of rolling module — up to 6 persons.

3 Capacity of rolling stock — up to 60 persons.

4 Track gradient — up to 15%, with a special design — up to 30%.

5 Transportation distance — up to 10,000 km.

6 The volume of high-speed intercity transportations — up to 1 million passengers per day.

7 Cost of high-speed route, excluding the cost of rolling stock, passenger stations and infrastructure — from USD 3 million per km.

8 Net cost of high-speed traffic — 5 times lower than the net cost of high-speed railway transportation, magnetic levitation trains and aircraft.

Competitive advantages:

- Decrease of capital expenditure for construction due to:

- significant decrease in acquisition of land required for the track and infrastructure;

- exception of earth embankments, excavations, tunnels, bridges, viaducts, multi-level interchanges and culverts;

- exception of fencing of linear part of the high-speed route;

- keeping the cost of rail-string overpass unchanged irrespectively of the type of terrain, strength of underlying soils and complexity of geographical and climatic conditions;

- decrease by the order of resource intensity for a string-rail overpass compared to conventional transport flyovers with solid roadbed.

- Reduction of operating costs:

- by reducing the consumption of energy;

- by reducing expenses for operating personnel and their wages;

- by reducing the volume of track maintenance and repair work;

- by avoiding the necessity to clean the track structure of ice and snow in winter period.

- Reduction of the net cost of high-speed traffic by three or more times.

- Possibility of development and land settlement on new territories in hard-to-reach places, comfortable to live in, — islands, mountains, sea shelf, etc.

- Possibility of combining the track structure and its supports with cable power lines and communication lines — wire, radio relay, cellular.

Environmental friendliness

1 Low resource consumption and low expenditures at all stages of the life cycle of the high-speed transport system.

2 High-speed track does not violate terrain, biogeocenose and biodiversity neighborhood.

3 The route does not destroy neighbouring fertile soil and vegetation growing on it (fauna and flora).

4 The track does not prevent:

- movement of ground and surface waters;

- movement of people, domestic and wild animals;

- operation of agricultural, constructional and special machinery.

Reliability and safety

1 Availability of anti-derailment device on the high-speed rolling stock.

2 Ten-fold margin of safety of bearing string elements in the transport overpass.

3 Stability to ice, glaciation, snowdrifts and dust storms.

4 Reliable operation at extreme air temperatures.

5 High stability to vandalism and terrorist acts.

6 Stability to natural disasters (with special design):

- earthquakes of magnitude up to 10 points on the Richter scale;

- floods and river overflows with water depth up to 10 meters and more;

- hurricane wind with speed up to 250 km per hour;

- tsunami with wave height up to 20 meters.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

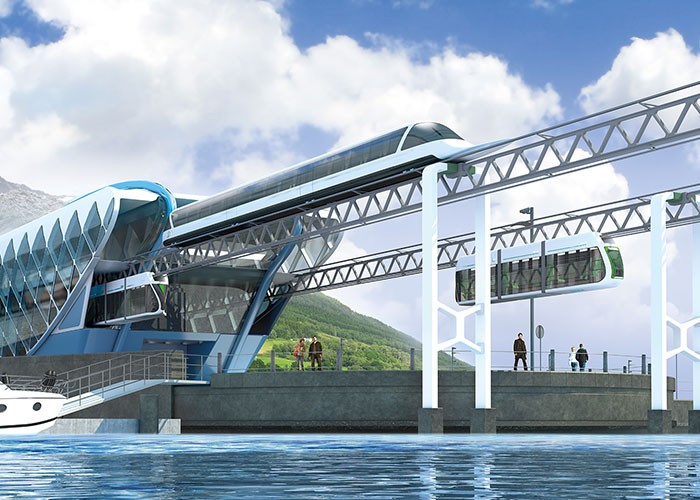

Urban Transport

Urban transport SkyWay is a unique infrastructure solution for towns, mega-cities and their suburbs.

Modern cities develop not according to the customary extensive way (the growth of the metropolis, the increasing population density), but by uniting with several nearby towns of different sizes by means of modern logistics and transport communications. Thus, a city is developing not due to the absorption of new areas, but as a result of increasing transport accessibility and eliminating distance as a problem.

Urban SkyWay transport is a result of many years of experience and unique technical solutions that provide all the basic criteria of quality transport services, such as:

- safety;

- accessibility and affordability;

- comfort;

- environmental friendliness;

- minimum power and resource consumption.

Urban SkyWay transport includes:

- rolling stock;

- track infrastructure;

- safety and complex control system.

The rolling stock of urban transport − unibus – is an automated self-propelled module on steel wheels of suspended or mounted type, designed to operate exclusively on Sky Way track infrastructure and provides for the transportation of people and cargo.

Urban unbuses can be supplied in various modifications taking into account specific features of the region of operation and customer requirements.

The capacity of a unibus is 14 people. They can be assembled in a train of up to 100 passengers capacity. Maximum travel speed in the city is up to 150 km/h. The motion drive of the unibus is electromechanical, with power supply from the contact catenary and/or on-board source of electricity.

Track infrastructure is designed to service the users of the urban SkyWay complex. It consists of a pre-stressed continuous bearing rail-string structure mounted on supports above the ground at the projected height according to customer requirements, and stations (logistics terminals).

The safety and complex control system is designed for automatic control of rolling stock, automated control of the power supply system, collection, storage, analysis of data on component parts of the complex and development of optimal (rational) decisions and control actions to ensure safe operation mode of component parts and the complex as a whole.

Key features of urban SkyWay transport:

1 Motion speed in a city — up to 150 km/h.

2 Capacity of rolling stock:

passengers — up to 100 people;

cargo — up to 10 tons.

1 Track gradient — up to 15%, with a special design — up to 30%.

2 Transportation distance — up to 200 km.

3 The volume of high-speed city transportations:

passengers in rush hour — up to 25 thousand people in one direction;

cargo — up to 1 thousand tons per day in one direction.

1 Net cost of high-speed city traffic — 2 times lower than the net cost of underground transportation, 3 times less than by tram, 5 times less than by a monorail way.

Competitive advantages:

- Decrease of capital expenditure for construction due to:

- significant decrease in acquisition of land required for the track and infrastructure;

- exception of solid roadbed, transport tunnels, bridges, viaducts, multi-level interchanges, overhead and underground pedestrian crossings;

- keeping the cost of rail-string overpass unchanged irrespectively of the type of terrain, strength of underlying soils and complexity of geographical and climatic conditions;

- decrease by the order of resource intensity for a string-rail overpass compared to conventional transport flyovers with solid roadbed.

- Reduction of operating costs:

- by reducing the consumption of energy and fuel;

- by reducing expenses for operating personnel and their wages;

- by reducing the volume of track maintenance and repair work;

- by avoiding the necessity to clean the track structure of ice and snow.

- Reduction of the net cost of high-speed urban transportation of passengers and cargo by two and more times.

- Possibility of sparing development and land settlement on new territories in hard-to-reach places, comfortable to live in, — islands, mountains, sea shelf, etc.

- Possibility of combining the track structure and its supports with cable power lines and communication lines — wire, radio relay, cellular.

- Improving the reliability and safety of all-weather and year-round operation of high-speed urban transport system in any climatic conditions.

Environmental friendliness:

1 Low resource and power consumption at all stages of the life cycle of the high-speed off-street urban transport system (project designing, construction, operation and dismantling).

2 High-speed track of overpass design does not violate terrain, biogeocenose and biodiversity of the adjacent natural city territory.

3 The urban route does not destroy fertile soil and vegetation growing on it.

4 The track does not prevent:

- movement of ground and surface waters;

- movement of people, domestic and wild animals;

- operation of constructional and special machinery.

Reliability and safety

1 Availability of anti-derailment device on the high-speed rolling stock.

2 Ten-fold margin of safety of bearing string elements in the transport overpass.

3 Stability to ice, glaciation, snowdrifts and dust storms.

4 Reliable operation at extreme air temperatures.

5 High stability to vandalism and terrorist acts.

6 Stability to natural disasters (with special design and minimum price rise):

- earthquakes of magnitude up to 10 points on the Richter scale;

- floods and river overflows with water depth up to 20 meters;

- hurricane wind with speed up to 250 km/h;

- tsunami with wave height up to 50 meters.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

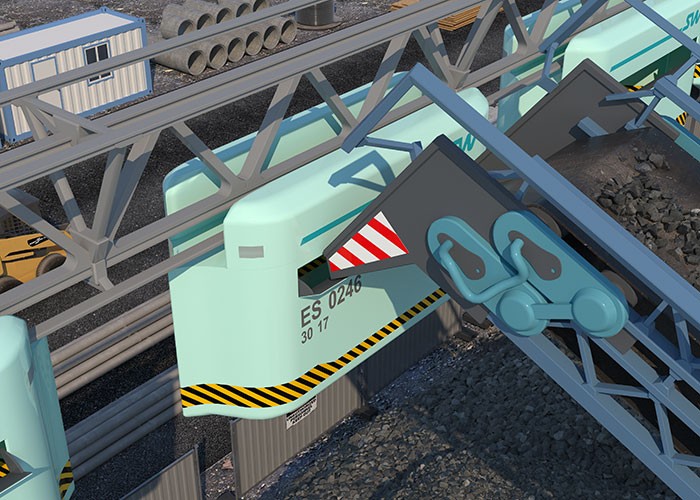

Cargo Transport

Competitive advantages of SkyWay cargo transport complex for transportation of rock mass

Expenses on transport are one of the most essential component of the total costs of extraction and processing of commercial minerals. This proves the need to justify the use of the most effective complex of transportation. However, a complete and comprehensive analysis of optimal transport complex is often not carried out. The preference of one or another mode of transport is determined mainly by a subjective opinion.

Currently, mining companies apply mainly the following competing technological transport systems: railway, suspended air-cable ways, conveyors and motor-road transport.

The main factors having the greatest influence on the choice of a transport complex for the mining business are:

- terrain and other specific features of construction area (ecological aspects, housing development, availability of natural and artificial water bodies, etc.);

- transportation distance;

- haulage volumes and type of cargo;

- the need for staff;

- capital expenses;

- operational expenses.

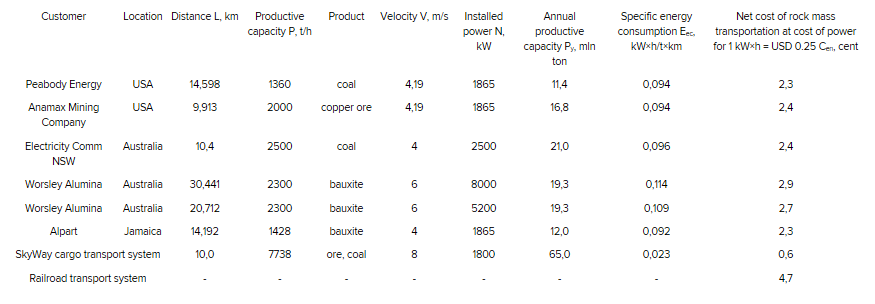

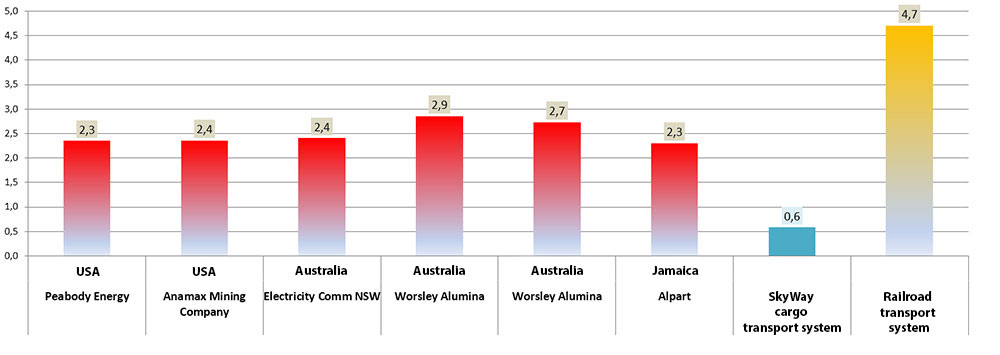

As practice shows, cable-belt conveyors have, in most cases, the lowest total cost (capital expenses and operating expenditures for the entire period of operation) for transportation of bulky materials over long distances (above 10 km). The table below shows the main technical characteristics of some of the world’s largest cable-belt conveyors. For comparison there are also data for the variant of applying SkyWay cargo complex with the capacity of 65 million tons per year (2.15 tons per day), unattainable for the competing transport systems.

The most important are [1]:

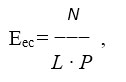

- the parameter that determines specific energy consumption for haulage of rock mass Eec, kW×h/t×km:

where

N – installed power, kW;

L – distance of transport system, km;

P – productive capacity of transport system, t/h.

- net cost of cargo transportation Сen (without depreciation expenses), cent/t×km:

Cen = Eec × СkW×h = 25 × Euc,

where

СkW×h = 25 cents – cost of power for 1 kW×h.

Table Comparison of the main technical characteristics of some of the world’s largest cable-belt conveyors and SkyWay cargo transport system

Net cost of rock mass transportation at cost of power for 1 kW×h = 25 cents

As the table shows, for the specified conveyor transport systems of overpass type (with the account of slight inclines on the route) calculated parameters are within the following ranges:

Eec = 0.092 – 0.114 kW × h/(t × km),

Cen = 2.3 – 2.9 kW × h/(t × km)

For example, for railroad transport as an alternative transport system, the index is:

Cen = 4.7 – 7.5 cent/t × km

SkyWay cargo transport complex is a product line of overpass type, intended for transfer of bulk cargo (transportation volume is up to 250 million tons/year). The overpass of the transport complex is a pre-stressed spatial truss structure mounted on supports above the ground. The height of the supports is such that it allows to pass freely over the existing buildings, highways, power lines, communications and other service lines.

On the overpass there is an operational rail-string track designed for a long unicar train, transporting bulk cargo with a total capacity of up to 100 thousand tons. To service the cargo transport complex and perform technological operations, there is a technological-maintenance rail vehicle travelling along a separate line, combined with the operating track.

The use of a rail-string technology and selection of optimal design parameters allowed engineers of the SkyWay Technologies Co. to reduce the specific resistance to the movement of cargo rolling stock and reach values of specific energy consumption on Сen to the level of 0.023 kW×h/t×km (taking into account slight inclines on the route of up to 3%). It also made possible to reduce the cost of haulage to 0.6 cents/t×km, which is 4−5 times less in comparison with alternative transport systems and 8−12 times less in comparison with railroad transport.

In addition, there is a huge potential in the operation of the complex in highlands. For example, if transportation occurs from a mountainous region to a seacoast or to an area located lower than the mining site, on the 500 km route distance sufficient is a total altitude difference of 1,500 meters for the complex not to consume electricity for ore transportation at all. Using regenerated potential energy of cargo descent from the mountains, SkyWay cargo transport complex will be able to exist completely autonomously, that is particularly important for undeveloped regions of the planet. The total cost of haulage by such a system would be even lower than that of the same system for flat terrain due to lack of electricity expenses.

The transport structure of the complex can be used to align high-voltage power lines, solar panels, communication lines, to arrange wind power plants on the supports.

An important aspect is lack of environmental problems arising from the construction and operation of SkyWay cargo complex. For example, while constructing a railway embankment, the natural hydrology of the area is changing, since, in fact, such embankment becomes a low-pressure dam, which acts as an artificial watershed. A significant problem is the railroad crossing of migration routes of animals that are dying in large numbers under the wheels of locomotives.

Fertile agricultural lands are withheld from cultivation for the construction of railway networks.

Cargo SkyWay transport system has none of these problems: the transport overpass is located at a height of 5−8 meters above the ground, supports are installed in every 40−50 meters and the area of land allocated for one intermediate support, does not exceed 2 square meters. Thus, 1 kilometer of route needs withdrawal of not more than 100 square meters of land with the account of anchor supports (which occupy up to 50 m2/km). Assembling of a transport overpass implies minimum manned technology; loading and unloading of rolling stock is done in motion, without stopping; the track is of all-weather type and has a great durability due to small loads on wheel shafts and the overpass. These technical and technological solutions have been tested on the experimental section of the track in the town of Ozyory, Moscow region [3].

Lack of environmental problems during the construction of the transport system is a significant advantage, because the number of nature-preserving measures (and, respectively, funds for their implementation) in this case is minimal. For example, the initial project cost of the gas pipeline in Alaska (USA) amounted to USD 600 million, but after protests from community and environmental organizations its construction was blocked. Then, after the implementation of all nature-preserving measures, which is particularly expensive in permafrost conditions, the pipeline was built, but its cost rose to USD 5 billion, i.e. 8 times more expensive.

There are known cases when large mining projects have been closed since the construction of a railway to the port did not pass ecological expert examination.

SkyWay cargo transport is a breakthrough in the field of bulk cargo haulage; it provides the opportunity to develop such deposits, which are uneconomical or impossible for development with the use of conventional modes of transport: in mountainous areas, nature conservancy zones, in tundra and the jungles. SkyWay technologies allow the transport to move on the gradient of up to 40% – and this means that the system is flexible, the overpass literally repeats the profile of the terrain, and the cost of track structure increases by only 25−30 % compared with the option for flat terrain.

The cost of SkyWay transport complex depends on many factors: traffic volume, country of implementation, terrain, natural, climatic and other conditions. The average cost of rolling stock, overpass, terminals and infrastructure, referred to 1 km length of the route, is equal to: for plain terrain − from USD 1.5 million/km, for rough terrain – from USD 2 million/km, for mountainous areas – from USD 2.5 million/km. For comparison: in Australian conditions a single-track cargo railway costs for the customer in the amount of USD 5 million/km.

With the appearance of SkyWay technologies, ore mining in many mountainous regions can become profitable. Even in ideal conditions for the existing transport systems, cargo SkyWay transport complex requires less operating expenses by 4−5 times at the same productive capacity, which will allow to save hundreds of millions, and even billions of dollars a year*. For mountainous conditions, cargo SkyWay transport system will significantly increase the profit compared to a conventional cable-belt conveyors, not to mention conventional railway transport, which in these conditions simply do not stand up to any competition. For example, the allowable longitudinal gradient of 0.9% makes railway men to pass through mountains and build tunnels, bridges and viaducts with enormous spans, designed for a giant load. It increases the railroad construction cost in a mountainous area by at least 2.5 times, and often makes the development of minefields unprofitable. In case of pessimistic prices, ore mining in mountainous areas becomes unprofitable when using railway transport, while, using SkyWay technology, profit remains at rather a high level. This feature provides for a company, using SkyWay transport technologies, not only the possibility to thrive in times, difficult for all others, but also to use this “economic weapon” to fight with competitors, achieving a complete monopolization of the industry in some aspects.

References:

1 Journal “Mining industry” No. 3, 2005, article “Cable-belt conveyors of great length”, authors: Andrew Lewis, General Manager, production line “Bulk material transportation” of Metso Minerals (UK) Ltd., England; L. Grebeneshnikov, marketing Director (wear protection and conveyors), “Metso minerals RUS CO”, Russia. (in Russian)

2 Journal “Mining Industry” No. 2, 2012, p. 96, article “Modern systems of transporting minerals and overburden rocks”, authors: A. A. Tverdov, Ph. D., IEEC mining engineer; A. V. Jura, Ph. D., IEEC consultant on economics and marketing, S. B. Nikishichev, Ph. D., Director of the IEEC. (in Russian)

3 Rational use of natural resources: resource and energy saving technologies and their metrological support / Materials of international scientific-practical conference, 22-24 June 2004, Petrozavodsk. – Moscow: Federal State unitary enterprise “VIMI”, 2004. – 385 pages; pp. 98 – 100, article “String transport system – transport of the XXI century”, author: A. E. Yunitskiy. (in Russian)

* For example, at the distance of 500 km transportation, a mining company that has a traffic volume of 65 million tons per year, will save (earn) on transportation of ore, as compared with the railroad: (0.047-0.006)×500×65000000=1,332.5 million USD per year. However, during the service life of the SkyWay system (50 years) savings will exceed USD 60 billion.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

SkyWay Seaport Transport

Sphere of application — cargo transhipment from SkyWay rolling stock:

- in bulk carriers — for bulk cargo (coal, ore, etc.);

- in tankers — for oil and petroleum products;

- in the container ships — for containers.

- transfer of passengers from SkyWay rolling stock to passenger ships.

Key features:

- port location — on the shelf in the open sea;

- natural depth of the sea in the port is 20—30 m and more;

- distance from the port to the shore: 1—10 km and more, both within territorial waters and beyond;

- cargo transhipment volume — up to 250 million tons per year;

- number of transit passengers — from 1 million people per year;

- cost of the sea port, excluding the cost of SkyWay access track, rolling stock, loading-unloading terminals and infrastructure — from USD 10 million.

Competitive advantages:

1 The possibility of arranging waterfront berth with depths of 20 m and more by using natural depth of the sea.

2 Lack of necessity for large, free and high-cost areas on the shore, with vulnerable ecosystem, as a rule.

3 Decrease of capital expenditure for construction due to:

- lack of necessity for dredging operations with the purpose of creating deep-water port area for vessels approach to the dockside ;

- lack of necessity for a berth wall, needed for ships mooring and protecting the shore from erosion by the surf;

- lack of artificial sea access channels in harbour waters and the port.

4 Reduction of operating costs by:

- simplifying the entry of vessels with deep draft, compared with entry in conventional ports;

- reducing the vessel demurrage while transhipping cargo and transferring passengers; minimizing the cost of port pilot service;

- improving the logistics of bulk cargo while working on the scheme: “ore deposit — SkyWay rolling stock — bulk carrier hold” instead of the traditional scheme: “ore deposit — rolling stock — unloading in the storehouse on the shore — loading from the shore storehouse into the other rolling stock — transportation to berth — overloading into the bulk carrier hold “;

- reducing the consumption of energy and fuel for transhipment;

- reducing expenses for operating personnel and their wages;

- automation of loading-unloading operations;

- reducing the volume of maintenance and repair works in the port.

5 Improvement of the quality of cargo, especially bulk (ore, coal, etc.), and increase of its selling price by reducing the number of loading and unloading transshipments.

6 Improvement of the reliability and safety of all-weather and year-round operation of SkyWay sea port on the shelf compared to a conventional port on the shore.

7 Environmental friendliness:

- low resource consumption and low energy consumption at all stages of the life cycle of SkyWay sea port (design, construction, operation and dismantling);

- SkyWay sea port does not violate the terrain, biogeocenose and biodiversity of sea shore neighborhood;

- SkyWay sea port does not destroy the fertile soil and its vegetation on the sea shore neighborhood;

- the absence of large-volume open storage areas and piles of bulk cargo on the shore (ore, coal, etc.) and in the coastal zone, which would pollute and litter the environment.

8 SkyWay sea port does not prevent:

- existing natural movement of water and natural underwater currents;

- movement and the natural migration of fish and marine animals;

- biogeocenose and biodiversity of the seabed in the port and harbor waters.

9 Reliability and safety:

- tsunami and tides in the open sea are not dangerous, because the wave height in them rarely exceeds one meter;

- waves in the open sea have less height and cause less danger for vessels than at the shore;

- sea port is not exposed to the surf due to its absence.

- high stability to vandalism and terrorist acts.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Flight Strips

SkyWay technologies Co. offers an innovative solution for the design and construction of flight strips (runways) for airfields. Such flight strips will have the features that fully meet the requirements and standards of the International Civil Aviation Organization (ICAO).

A flight strip will be produced in the form of a pre-stressed cast reinforced concrete slab, clamped at the ends. A solid pre-stressed string reinforced concrete slab with a thickness of 15−25 cm, clamped at the ends, by its bearing capacity and strength will replace traditional concrete runway coverage of 30−50 cm thickness. It is justified by the strength calculations, made according to traditional methods in accordance with the acting national and international regulations. These calculations and studies on specific objects are to be done jointly with specialists of Project Bureaus, designing traditional runways (in Russia it is the State design and research Institute “Aeroproject”).

The proposed technology excludes the need for expansion joints, improves evenness, strength and durability of the runway coverage.

A flight strip built with the application of SkyWay technologies

This reduces requirements to the bearing capacity of gravel and sand cushions and underlying soil, simplifies the configuration of other elements of an airfield. The joints in the coverage will not be destroyed because of their absence. They will not produce dynamic impacts not only on the chassis of the aircraft, but also on the passengers in them. At present, for example, passengers, even while inside the aircraft cabin in soft chairs, can count the number of expansion joints on traditional runways during each takeoff and each landing.

A flight strip with expansion joints built by traditional technologies

If necessary, this solid reinforced concrete slab can be covered with a layer of asphalt concrete, which will also have no expansion joints and temperature cracks. Alongside with significant improvement of operational characteristics, such runway will be considerably less costly than a traditional one.

The use of SkyWay technologies in the construction of runways will reduce costs by 20−30 percent or more alongside with improvement of their operational features and increase of their service life.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Vacuum Glass

The pace of development of window industry can be compared in rate with the pace of development of such modern branches of our everyday life, as computers and means of communication. Modern windows, alongside with high aesthetic, ergonomic and architectural requirements, must perform one very important function, that is − to save energy in our homes. For example, according to the U.S. Department of Energy, the total energy losses through windows in residential and industrial sectors cost American consumers USD 25 billion a year. In hot countries (India, countries of the Arabian Peninsula, Africa, Australia, etc.) these losses are even more, but have the opposite sign — coolness created by air-conditioners should be kept in premises. These official data served as a great economic motivation for the development of energy-efficient glazing systems for buildings.

A common misunderstanding is an anecdotal evidence that ordinary double-glass units contain vacuum. This is not so. Ordinary double-glass units are filled with dry atmospheric air. They are really “insulating”, “isolating”, but have no vacuum. To improve the thermal insulation, the internal space of a double-glass unit can be filled with inert gases (argon, krypton, xenon or mixtures thereof) with smaller values of thermal conductivity and larger values of viscosity compared with air. Losses due to radiant heat exchange can also be reduced by using glasses with special low-emission coating on one or both inner surfaces of the unit glasses.

The use of vacuum as a thermal insulator is not a new concept. It was described in the patents even in the nineteenth century. As for the double-glass units, vacuum application was designed to eliminate heat loss due to heat conductivity and convection in the gas layer between the glass sheets. Currently, persistent searching of the optimal production technology of vacuum double-glass units continues in the world, for example, within the framework of the European Union project titled “Production technology of highly-insulating vacuum glazing”, other initiative and investment projects. All of this is a real evidence of good prospects for the application of vacuum double-glass units as a means of energy-efficient glazing of buildings.

High durability (at least 20 years) and good heat insulating properties are obtained already at the thickness of the vacuum gap of 0.05–0.1 mm (the gap in the known technologies is created by using special filling pads, which are glass beads, thin plates of stainless steel or ceramic inserts, fixed with a spacing of 20−40 mm). Such pads allow the glass unit to withstand enormous compressive strength of atmospheric air, which is approximately equal to 10 tons per square meter of glass surface.

In the proposed string-designed unit, vacuum gaps reach the thickness of 1–2 mm (this technology is one of the SkyWay know-how). A large vacuum gap, obtained with a minimum number of “bridges of cold”, will significantly increase the service life (increased vacuum volume degasifies longer) and will further improve the insulating properties of the vacuum double-glass unit without increasing its cost.

When building a greenhouse or a winter garden with vacuum glass units in a cold climate, energy expenses for heating will be decreased by 90%. Solar power stations with vacuum glass units will heat water not to 60°C, but to 90°C, that is, they are transferred from installations for hot water supply to the category of installations for building heating. New technologies give scope for the imagination of architects and builders. Imagine a normal warm house with brick walls of 1.5 meter thickness and the same warm house with a wall thickness of 15–20 mm, made of vacuum double-glass units. Or — a 100-storeyed skyscraper in Sydney (moreover, with a high-rise track of “SkyWay metro”), with power consumption for air conditioning in summer and for heating in winter by several times less than for a traditional skyscraper.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Bridges, Viaducts and Overpasses

Construction of bridges, viaducts, overpasses and other extended transport structures in SkyWay string technology

SkyWay Technologies Co. offers an innovative solution for the design and construction of road, railway and pedestrian bridges, viaducts, overpasses and other extended transport structures (hereinafter — bridges). Such bridges will have features that are fully consistent with the existing national standards. For example, in the Russian Federation such a regulatory document is the Construction Norms and Regulations 2.05.03-84* “Bridges and pipes”, which applies to rail, road and pedestrian bridges, bridges for metro lines and speedy trams, as well as bridges, combined with rail and road transport. In addition, string bridges correspond to national standards for the design of steel structures (in Russia it is the Construction Norms and Regulations II-23-81 “Steel structures”), all the provisions of the European Norms Project (ENV) and the new US bridge standards (AASHTO).

It is proposed to construct string bridges in the form of a pre-stressed continuous structure of steel-reinforced concrete, clamped at the ends to anchor supports, which contains road coverage, or coverage for pedestrian bridges. Solid pre-stressed string structure, clamped at the ends, by its bearing capacity and strength will replace traditional steel, reinforced concrete or steel-reinforced concrete bridge span superstructures. It is confirmed by strength calculations, made by traditional methods in accordance with the applicable national and international standards. It is reasonable to do these calculations and studies on particular bridges jointly with specialists of the existing bridge design offices, having the experience in the design, construction and operation of suspended and cable-stayed bridges, which are structurally closest to string bridges.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Visually string bridges are similar to traditional ones because the know-how are hidden inside the structure, apart from their glaring lightness and delicateness of the structure. Thus, the proposed technology excludes the need for expansion joints throughout the whole structure, regardless of its length. It increases the smoothness, strength and durability of traditional coverage on bridges, reduces by times consumption of conventional structural materials and, consequently, reduces the cost of structures. This significantly decreases the load on intermediate supports, that are often placed in water, and accordingly, reduces the requirements for bearing capacity of soil. This also simplifies the design of other elements of the bridge structure. With significant improvement of operational features, such bridge would be much cheaper than traditional bridges. It is easily confirmed and justified by calculations made by traditional methods in accordance with the applicable national and international regulations.

Provided the load-bearing structures of traditional bridges are produced in string technologies (in the form of pre-stressed load-bearing beams or string trusses), their cost is reduced by 2–3 times or more alongside with increasing their durability and improving performance features. In particular, the coverage of motor-road bridges will be arranged without expansion joints, as the string bearing structure of the bridge will be produced continuous (uncut) throughout its entire length, without any transverse gaps and joints. For their erection, string bridges do not require non-traditional materials and technologies and can be built by existing bridge teams with existing construction equipment and construction machines.

Source: http://sw-tech.by/production

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

SkyWay Linear City in Abu Dhabi Concept

The global market is waiting for the emergence of a fundamentally new transport and infrastructure technology meeting the following requirements:

- economic, resource and fuel efficiency;

- all-round safety, including environmental friendliness;

- freight and passenger applicability;

- a wide range of available distances;

- a wide range of speeds up to 500 km per hour;

- ruggedness and suitability to extreme climate conditions.

SkyWay technologies meet all of the above.

Transport and infrastructure arm of SkyWay technologies is a multitude of transportation and development and engineering solutions fitting well into the natural environment, creating a comfortable, environmentally friendly, and safe urban habitat. For simplicity this complex is hereinafter referred to as Linear City.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Linear City is a cluster-type urban settlement, where the surface of the earth is meant for pedestrians and green plants, while transport, energy and information networks are elevated above the ground on the “second level”.

There is only one mode of transportation in the city – horizontal lifts connecting the high-rise towers, spaced at 500 meters and more (up to 3 km) from each other and placed along one line, or several parallel and intersecting lines.

SkyWay Linear City can be built in the desert, at waterlogged and challenging construction sites (difficult terrain), as well as offshore.

Line City concept for Abu Dhabi was developed in accordance with the emirate’s objectives set forth in the following framework documents:

- Abu Dhabi Economic Vision 2030;

- Urban Planning vision 2030;

- Plan Capital 2030;

- Plan Maritime 2030;

- Plan Al Ain 2030;

- Plan Al Gharbia 2030.

SkyWay transport and infrastructure technologies underpinning the Linear City meet all the key requirements of the Estidama national development system.

The basic principle of the construction of each infrastructure cluster is that it is a pedestrian quarter, in which comfortable low-rise buildings are put between the multi-functional high-rise buildings connected by a horizontal lift, with widespread landscaping of urban areas and use of renewable energy sources.

The horizontal lifts are the key element of the system – they are the transport arteries connecting neighboring high-rise buildings, settlements, residential, shopping, entertainment and other clusters, allowing for comfortable transit within a few minutes. An important advantage is that the cost of the public transport can be included, as it is done with conventional elevators in the buildings, into the square meter price of the Linear City premises, while keeping the average market price for new residential premises.

In fact, when implementing the SkyWay Linear City development project, the Abu Dhabi Department of Transport is basically pursuing the state policy on modernization of public transport while not spending the budget.

At the same time substantial savings are offered due to:

- reduced cost of construction of paved roads – up to 90%;

- reduced cost of maintenance of paved roads – up to 90%;

- reduced harmful emissions into the ambient air – up to 90%;

- reduced energy consumption by transport – up to 90%;

- reduced municipal transport costs – up to 90%;

- reduced costs of irrigation of green areas due to recreation of fertile soil – up to 90%;

- reduced cost of urban landscaping – up to 100%.

The benefits offered by SkyWay transport and infrastructure complex:

1 Low cost of construction and transport services

Construction of the SkyWay transport complex is 2-3 times cheaper than a railway (streetcar) and 3-5 times than a motor roads system, 10-15 times cheaper than monorail and 15-20 times cheaper than magnetic suspension trains, while offering 3-5-fold lower cost of transportation.

2 Low power consumption

Power consumption is 5-7 times lower than that of the existing transport systems that use steel wheels or magnetic cushion, 15-20 times lower in comparison with transport running on pneumatic tires (motor vehicles) or hovering vehicles (aviation, WIG, helicopters).

3 Minimal footprint

The land plot required for the transport and infrastructure complex is roughly 100 times smaller in comparison with road and rail (tram) systems, and when using the suspension system for connecting urban high-rise buildings there is no need for expensive land allocation for transport at all.

4 Full automation

Automation of the transport and infrastructure complex and optimal transport logistics – in the Linear City the average home-to-work commute will not take more than 15-20 minutes at distances up to 15 kilometers.

5 Unprecedented safety

High level of transport and environment safety and anti-terrorist security, as there are no intersections, pedestrian crossings, oncoming traffic with the risk of head-on collisions, while the high-rise string-rail track structure has a tenfold safety factor and is not accessible for vandals, and the rolling stock is equipped with a derailing-prevention system.

6 High-speed performance

Public transport – up to 120-150 km/h; intercity high-speed transport – up to 450-500 km/h.

7 Minimal operating costs

Operating costs are 5-7 times lower than in case of the motor road system, and 2-3 times lower than those of the rail (streetcar) transport.

8 Using renewable energy

The SkyWay transport complex uses electric motors for efficient and low-cost “steel wheel – steel rail” coupling (including use of a unique motor-wheel) and can cover 100% of its energy needs with renewable energy – solar and wind.

9 Restoring the fertile soil

It is possible to restore fertile soil and natural ecosystems – fauna and flora (SkyWay-Agro technology) – in any habitat, including in the desert.

10 No harmful impact on people and the environment

Harmful impact – exhaust gases, noise, vibration, electromagnetic and other radiation are 15-20 times lower than those of the road systems and 2-3 times lower than in case of rail (streetcar) and monorail tracks.

11 Cost- and time-efficiency

Cost and time saving for passengers and shippers: time of city transit (delivery of goods) is reduced by up to 1-1.5 hours per day, translated into up to 20-30 USD per day per passenger or ton of cargo.

12 Fast payback

SkyWay transport and infrastructure complex has unprecedented payback period: 2 to 3 years.

To illustrate the layout of SkyWay Linear City we have chosen the difficult and hard-to-get-to Al Hudayriat Island to the south of Abu Dhabi (the state reserve lands).

Bird’s eye view of Al Hudayriat Island (Google Earth), 2015.

The following are the options for placement of SkyWay Linear City on the Al Hudayriat Island showcasing various concepts of desert and inaccessible areas reclamation in the Emirate of Abu Dhabi:

- Option 1: National Park on the Al Hudayriat Island with SkyWay Linear Cities around the perimeter of the island and off the shore.

- Option 2. Eco-city on the Al Hudayriat Island with the jungle and the SkyWay linear city off the shore.

- Option 3: Cluster-type Ecocity on the Al Hudayriat Island with Skyway Linear City off the shore.

- Option 4: Cluster-type Ecocity on the Al Hudayriat Island with the jungle and the Skyway Linear City off the shore.

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Option 1: National Park on the Al Hudayriat Island with SkyWay Linear Cities around the perimeter of the island and off the shore

Option 2. Eco-city on the Al Hudayriat Island with the jungle and the SkyWay linear city off the shore

Option 3: Cluster-type Ecocity on the Al Hudayriat Island with Skyway Linear City off the shore

Option 4: Cluster-type Ecocity on the Al Hudayriat Island with the jungle and the Skyway Linear City off the shore

Every proposed development project is revolutionary in terms of its infrastructure performance and can be accepted by the customer for implementation.

For more details – see the attached commercial offer “SkyWay Linear City in Abu Dhabi“.

Source: http://rsw-systems.com/news/skyway-linear-city-in-abu-dhabi?lang=en

SkyWay UniMobile

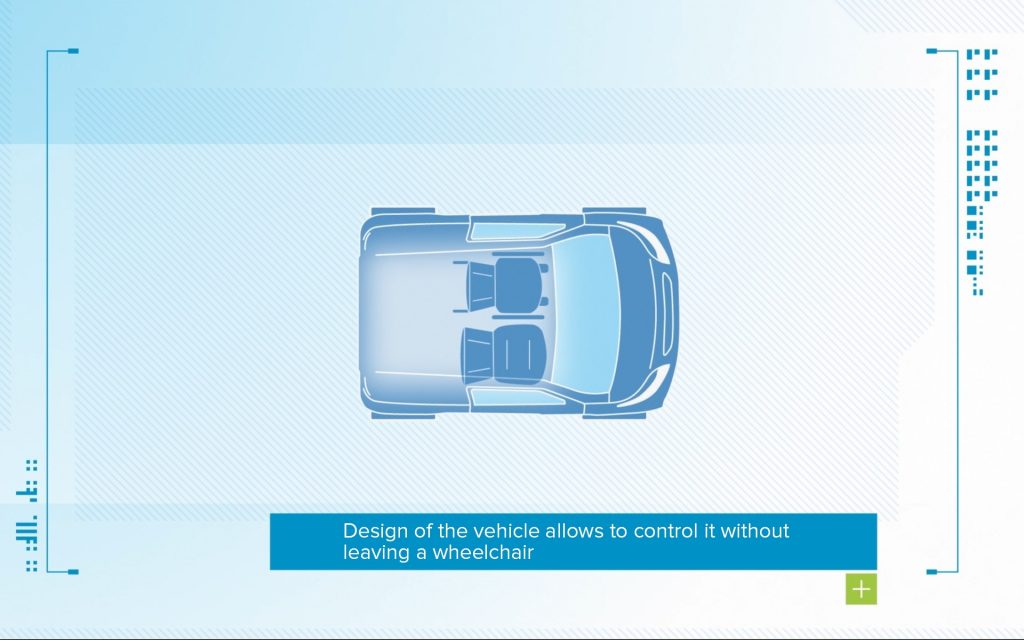

We continue the series of publications on the latest developments that were demonstrated to the public during EcoFest 2018. One of them is an electric vehicle for people with disabilities (unimobile).

For the first time in history, the design of this vehicle is based on an engineering solution providing a disabled person with the opportunity to drive a car being in a wheelchair.

“Actually, everything we do is filled with humanism: with the only correct attitude towards the world through love to the entire Mankind and to each person”, commented General designer of SkyWay Anatoli Yunitskiy on the development in his speech. “We have many people with disabilities among our investors including wheelchair invalids and I promised to help them by expanding their communication possibilities providing new opportunities. Not only for our investors. About 130 million people in the world are disabled wheelchair users, who depend on mobility to receive jobs. With this electric car they can become, for example, taxi drivers or pizza deliverymen. The driver will ride into the car in a wheelchair and, sitting in it, will be able to drive it. The chair itself is designed as a driver’s seat with an electric drive, in which one can drive 40 km at 20 km/h speed, that is, the wheelchair itself, which has no analogues in the world, is a small electric vehicle. We will show this development at a specialized exhibition in Moscow in September this year to attract maximum attention not only to the development, but also to the problem of mobility for people with disabilities.”

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

Presently there are several solutions for transportation of invalids in the world, but all of them are mainly based on re-equipment of serial cars.

– Minibuses equipped with lifting mechanisms and fixing of wheelchairs inside with tightens belts;

– Robotic systems that fold a wheelchair and load it in the luggage compartment automatically. But for the user it remains necessary to move independently from the wheelchair to the driver’s seat and back;

– Vehicles of class L7 (Quadrocycle), however they have significant limitations in features: weight – up to 400 kg, engine power – not more than 15 kW and maximum speed up to 45 km/h;

– Each of these options has its own set of negative qualities and cannot fully serve as a full-fledged solution.

They do not combine all the necessary requirements that are solved in UniMobile:

– While working out the technical concept of UniMobile, the main task was to provide disabled people with individual mobility and the maximum degree of independence;

– UniMobile, being a fully-featured car, will allow disabled people to fully realize their potential – to reach their place of work, study, leisure, to lead a more independent way of life;

– UniMobile was designed taking into account the ergonomic features of people with disabilities and disabled wheelchair users. As a result, the driver or passenger does not need to leave the wheelchair, which is also an automobile seat;

– A specially designed lock reliably fixes the wheelchair to the body and ensures safety of the user while driving. A similar lock fixes the passenger seat, which makes it possible to easily change the wheelchair and the seat if necessary. The car will not start moving if the lock is not fixed: a light indicator will let you know about it;

– Hand controls are comfortable and functional; they duplicate conventional pedals and switches;

– Access to the vehicle is arranged in such a way that the user, not leaving the wheelchair and without any assistance, can get into the cabin through a special ramp-lift located in the rear part of the body and controlled with a remote console. Light and sound indicators accompany and secure the process of boarding/de-boarding the driver and passenger;

– Reverse-hinged doors and the seat turning mechanism provide a more comfortable boarding.

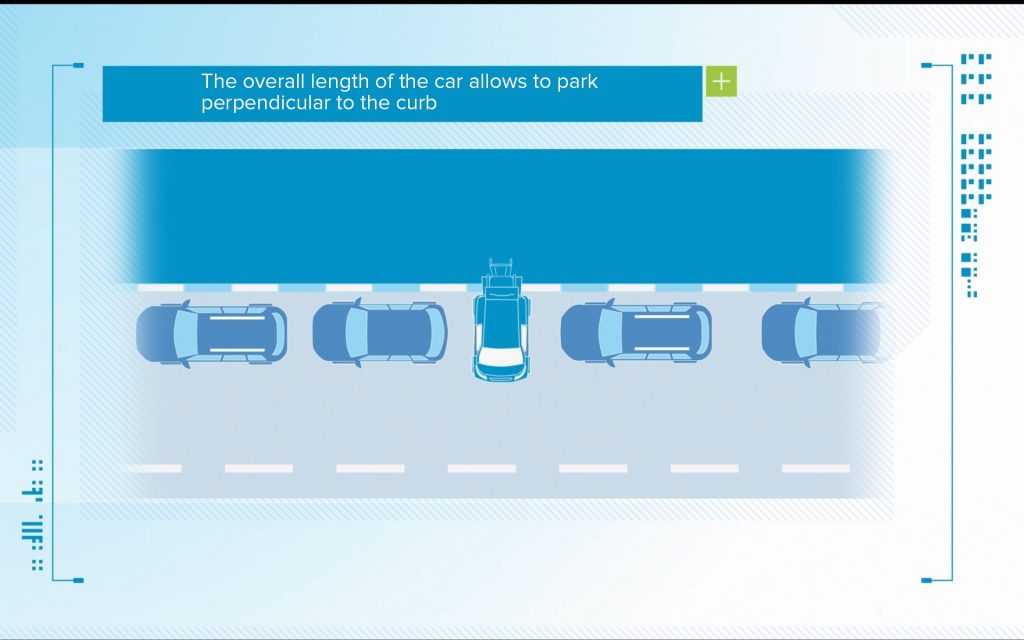

The overall length of the car allows to park perpendicular to the curb. Such parking provides boarding/de-boarding directly on the sidewalk. This feature also allows to park at standard parking spaces, not just at specially reserved sites.

– A parking radar and rear view camera simplify parking and increase safety;

– The use of rear-view cameras with LCD-displays instead of conventional mirrors provides the necessary overview and image quality.

– The car is equipped with an electric drive with a recovery system, which, in addition to economy, has a low level of toxic impact on the environment. The absence of a gearbox makes control easier;

– When transporting passengers in wheelchairs by the accompanying driver, the former are also provided with a comfortable boarding/de-boarding using a ramp-lift;

The vehicle meets all the safety requirements applied to M1 class cars and can be used on public roads.

Technical specifications:

– Maximum speed – 100 km/h;

– Drive range – 120 km;

– The curb weight – about 990 kg;

– The battery is charged from in-home network;

– The battery is charged from in-home network;

– The time of full charging is 10 hours.

As an option, UniMobile can be equipped with a wheelchair using electric drive and a cruising range of up to 40 km.

We remind that from 4 to 20 August 2018 we hold a contest for the best name to the first prototype of the SkyWay UniMobile. If you want to take part and compete for the top prize in the amount of 100,000 investment shares, enter the website UniMobile.by and fill out a simple participant form.

The name of UniMobile will be announced for the first time at the specialized exhibition “InvaExpo. Society for All” to be held on September 12-14, 2018 onsite of the Exhibition of Economic Achievements in Moscow.

Source: http://rsw-systems.com/news/unomobile-skyway

SkyWay Waste Disposal Plant

More info about this to come soon!

Our team is ready to help you

Anthony, Thomas, Christiane and Paso (Santeri)

You can contact us on Facebook and Skype for more information or help with the setup of your account

Skype: Anthonyvdv – Facebook Message: https://www.facebook.com/Makemoneycorp/

Join SkyWay Today – Join the Ecological Future of Tomorrow

Register your SkyWay account today

Ask our help with the setup and verification of your account

* * * * * *

Transport Solutions * Eco Houses * Eco Techno Park * Technologies

Anatoli Yunitskiy * SkyWay Capital Opportunity * Project Stages